SELF-SEAL®

Self-Seal® O-Ring Type

Positive Sealing–Pressure and Vacuum

Cold-Formed for Superior Strength and Uniformity

High Re-Usability

Optional Self-Locking Capability

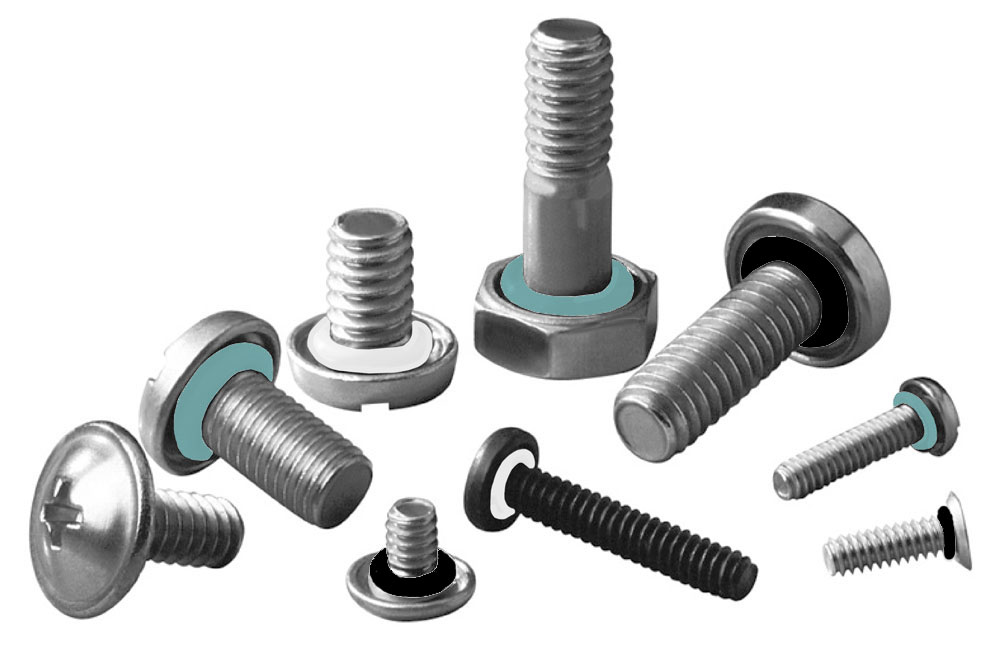

Self-Seal® fasteners, manufactured exclusively by Long-Lok, are designed to provide the optimum combination of sealing and fastening in one complete unit. They are cold formed for strength and uniformity, and then assembled with O-rings capable of sealing almost any fluid or gas.

Self-Seal® fasteners overcome all these limitations by placing an O-ring under the head for sealing. With this elegant solution, Self Seal fasteners offer these unique advantages:

• Assemble mating components using standard torque values.

• Specify any common surface finish.

• Metal-to-metal contact.

• High re-usability.

• Positive sealing from either side of the assembly.

Self-Seal fasteners are designed and manufactured with a cold-formed groove beneath the head of the fastener. As the fastener is tightened, the O-ring is compressed, squeezing the O-ring between the groove and mating surface to complete the seal. The design of the groove controls the amount of compression to the O-ring. And because O-rings retain their elastic memory, Self-Seal fasteners are reusable time after time. The O-Ring groove is optional for 100° flathead fasteners. Standard 100° flatheads are without the O-Ring groove.

Typical Applications

• Motors

• Cabinets and enclosures

• Sensors and instrumentation

• Internal combustion engines

• Gear pumps

• Fuel tanks

• Transmissions

• Gear boxes

• Air cylinders

• Pressure gauges

• Computer disk drives

• Motion control valves

• Missile tank

• Wet wings

Military Specifications:

MIL-DTL-18240

| Material | Description | Key Uses | Temp. Range (Dry Heat Only) | Color |

|---|---|---|---|---|

| Buna-N (Nitrile) | Most common seal material. Excellent resistance to petroleum-based oils and fuels, silicone greases, hydraulic fluids, water and alcohols. Low compression set, high tensile strength, and high abrasion resistance. Oil resistant applications. | Oil resistant applications. Low temperature military uses. Automotive, marine, aircraft fuel systems. | -40°F to 250°F | Black |

| Viton® (Fluorocarbon) | High temperature resistance and outstanding chemical resistance. Low gas permeability and high resistance to swelling in gasoline and gasoline/alcohol blends. Resists ozone and U.V. light. Perhaps the “ideal” O-ring material. Aircraft engine sealing. | Automotive fuel handling systems.Hard vacuum service. Wide chemical exposure situations. High temperature/Low compression set applications. | -20°F to 400°F | Black |

| Silicone | Made from silicone, oxygen, hydrogen and carbon. Excellent retention of flexibility and low compression set characteristics. One of the widest temperature ranges for elastomers. | Static seal in extreme temperatures.Medical devices. Meets FDA regulations. | -75°F to +450°F | Red |

| Ethylene Propylene | Copolymer of ethylene and propylene (EPM), sometimes combined with a third co-monomer (EPDM). Excellent ozone and chemical resistance characteristics. Provides effective resistance to steam (400?F) hot water, silicone oils and greases, dilute acids and alkalies, alcohols and automotive brake fluids. | Outdoor weather resistance.Hydraulic and automotive brake systems. Automobile cooling systems. Water appliances. | -60°F to +300°F | Black |

| Fluorosilicone | Combines the good high and low temperature stability of Silicone with the fuel, oil, and solvent resistance of Fluorocarbon (Viton®). Suitable for exposure to air, sunlight, ozone, chlorinated and aromatic hydrocarbons. | Aerospace fuel systems.Fuel emission control systems. Static sealing applications. | -70°F to +400°F | Blue |

| Neoprene (Chloroprene) | One of the earliest of the synthetic materials to be developed as an oil resistant substitute for natural rubber. A homopolymer of chloroprene (Chlorobutadiene). Good resistance to ozone, sunlight and oxygen aging; low compression set. | Components in transportation industry.Recommended for exposure to weathering. Preferred material for refrigeration industry. FDA listed for food and beverage industry. | -45°F to +250°F | Black |