TEK-LOK®

Tek-Lok® Pellet Type

-320°F to +500°F

Reusability per IFI 124, IFI 524 and MIL-DTL-18240

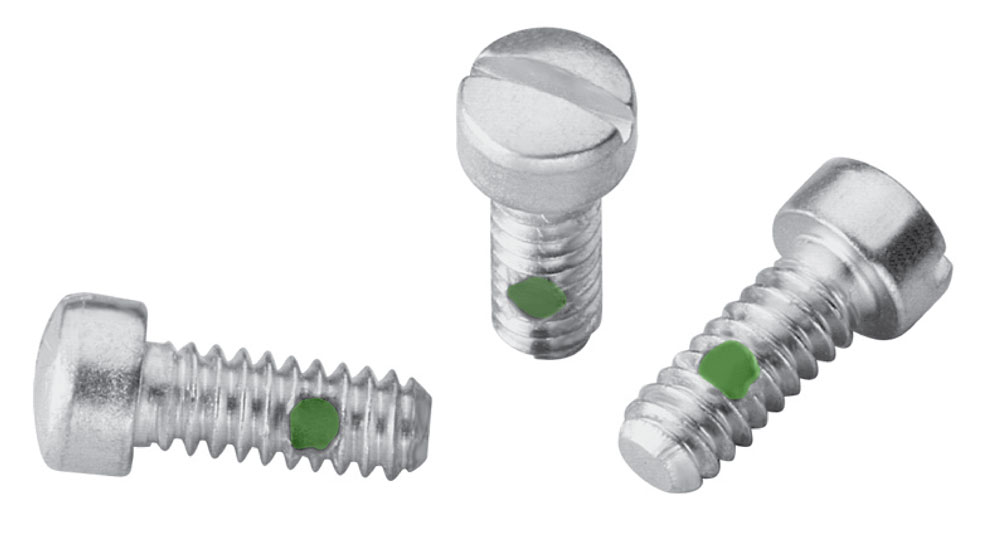

Tek-Lok® self-locking threaded fasteners obtain locking action from an engineered plastic pellet compressed into a hole drilled in the threaded region of the fastener, to a depth slightly below the root of the thread. Pellet size and location are standard but can be altered to meet special requirements.

Female threaded items

All standard nuts and most female threaded items can be made self-locking by drilling through the wall of the part and installing and swaging in place a nylon pellet. In some applications the pellet can be installed from the inside without drilling through the wall. Contact Long-Lok before specifying this design.

Specialty and Hard-to-Engineer Parts

Special parts can be produced with Tek-Lok pellets. Contact Long-Lok’s engineering group for unusual thread sizes, materials, thin wall conditions, short parts—where standard pellets do not appear applicable.

Clearance Hole

The locking element in Tek-Lok commercial fasteners can protrude above the crest of the thread, to approximately .010” over the maximum major diameter of the fastener. Therefore, a clearance hole of about .015” larger than the maximum major diameter of the fastener is recommended to allow for passage of the locking element, and the mating thread should be chamfered .020/.030 over the major diameter to insure good compression and locking action of the insert. Consult factory for special clearance hole or chamfer requirements.

Engagement Revolutions

Ideal performance of Tek-Lok commercial fasteners is obtained when the locking element has engaged the mating thread for five revolutions (threadpitches) or more. However, in many applications excellent performance is obtained with considerably less engagement. In general, the minimum length standard Tek-Lok fastener readily obtained can be determined by noting that two full pitches of thread should exist beyond the locking element (L dimension) for either proper performance or manufacturing ease.

Drilling and Tensile Strength

Extensive, independent test data demonstrates that when used properly, the tensile strength of Tek-Lok pellet type fasteners are not adversely affected by the drilled holes used to accommodate the locking element. Sizes of ¼” diameter and smaller may exhibit a very slight reduction directly in the drilled hole area. However, similar test data has shown that a high tensile strength margin remains; all parts still meet minimum specification requirements. Torsional strength for these parts is only affected in sizes smaller than #8, and then only when tightened beyond yield strength. Shear strength is not lost in any size; high shear bolt grips are not altered.

Military Specifications:

MIL-DTL-18240

Military Standards:

MS15981

Commercial Standards:

IFI 124, IFI 524 (Metric)

| Materials | Color Code | Operating Temperature Range | Material Specification |

|---|---|---|---|

| Polycap Nylon | Green | -60°F to +250°F; -51°C to +121°C | ASTM-D-4066 |

| PCTFE (Kel-F®*) | Blue | -320°F to +390°F; -196°C to + 199°C | AMS 3650 |

| Vespel® | Brown | -450°F to +500°F; -268°C to + 260°C | N/A |

| Thread Size | #0 | #1 | #2 | #3 | #4 | #6 | #8 | #10 | 1/4 |

|---|---|---|---|---|---|---|---|---|---|

| "L" Patch Length | .06 | .07 | .08 | .09 | .14 | .16 | .17 | .19 | .24 |

| Thread Size | 5/16 | 3/8 | 7/16 | 1/2 | 9/16 | 5/8 | 3/4 | 7/8 | 1 |

| "L" Patch Length | .27 | .30 | .31 | .33 | .38 | .41 | .47 | .52 | .52 |